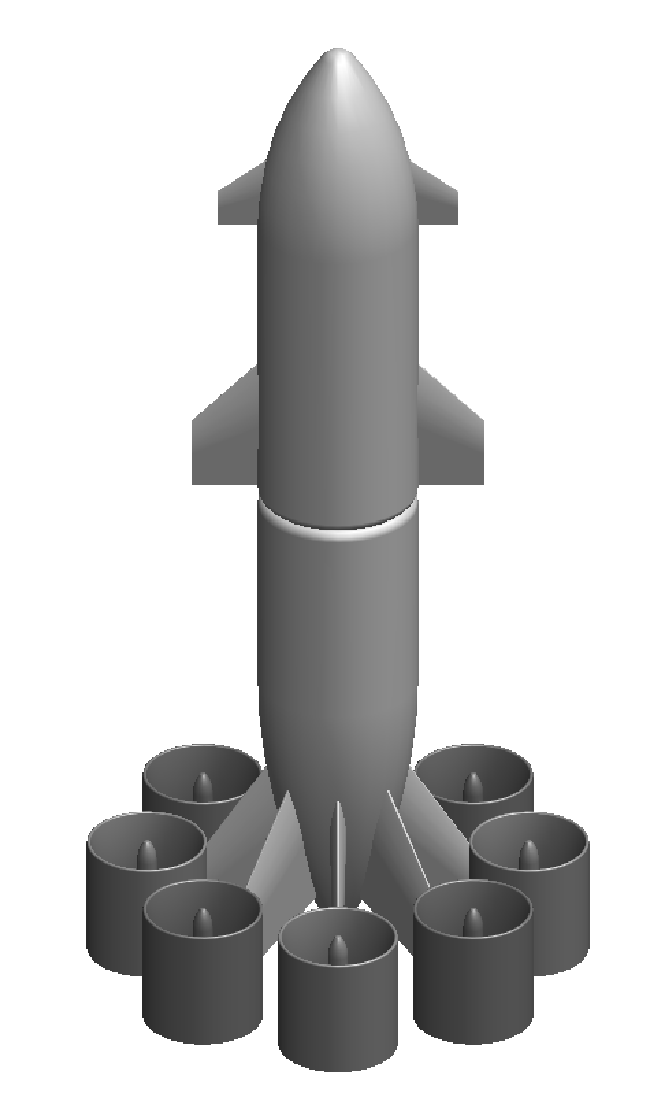

Electric Ejector Ramjet First Stage Low-cost Launch

Summary:

Electric ejector ramjet first stages present another pathway to greatly reduce the cost and increase the convenience of orbital launch beyond what reusable two stage rocket vehicles like Starship and New Glenn are capable of. Electric ejector ramjets use an electric air compressor followed by a combustion chamber to create high speed jets that entrain air in the intake of the ramjet. This enables the ramjet, or scramjet, to operate from zero speed and uses substantially less electrical energy than a pure electric ramjet that uses an electric fan to compress air in the ramjet intake. It also avoids intake obstruction via the electric fan once the ramjet is at speed. Electric ejector ramjets are perhaps the simplest, lightest, lowest cost, and most efficient engine for supersonic and hypersonic flight that can produce thrust from zero speed and they enable simple low-cost supersonic and hypersonic flight vehicles. They can have very high thrust to weight ratios - sufficient for vertical takeoff and landing systems, including first stages for suborbital and orbital vehicles. Being airbreathing they have much higher ISP (efficiency) than rocket engines.

The first to achieve launch costs of ~$100/kg wins data centers, AI, the internet, global high speed transport, and space. This is the tipping point where data centers move to space to take advantage of much lower cost solar energy and scale exponentially. Scaling rates are so fast that the first to get there will gain a cost reduction advantage that will result in a near unassailable monopoly. Aeroelectric first stages, which can carry the rocket vehicle to high altitude in a fast, safe, and highly reliable manner avoids aero-losses and enables much smaller rocket vehicles. They can achieve half the costs of two stage reusable rocket systems and can be much faster and lower cost to develop. Electric ejector ramjet first stages, although a little more expensive and harder to develop, have similar advantages to aeroelectric first stages, but can stage at higher supersonic and even hypersonic speeds - more comparable to two stage rocket systems, significantly reducing the performance requirement of the upper stage.

Some quick background:

The tipping point for data centers moving to space and scaling exponentially is ~$100/kg and we are currently in a new and even more critical space race for the future of AI, the internet, and most everything else. The U.S. has effectively already lost the AI race because it bet on having the best AI models, not the infrastructure to run them, the lowest cost compute, and the ability to scale and monetize AI in the physical world. Under ideal circumstances it might take a decade or more for the U.S. to regain these capacities, but this race, along with many others, will likely get decided in the next 2-3 years. The pace of new technology has greatly increased and with greatly accelerated hardware scaling rates the first mover advantage quickly results in a cost reduction advantage that leads to an effectively unassailable monopoly. There is little hope of the U.S. regaining the lead - the U.S. would need to develop and scale new technologies and reinvented supply chains within the next 2-3 years. Space (and military) is almost the only area in which the U.S. still holds a significant technological lead. However, the U.S. is about to quickly lose space (and military), like it has lost low-cost energy, batteries, electric vehicles, humanoid robots, critical materials, manufacturing, low-cost compute, and so forth. With China having three companies scheduled to test reusable first stages by the end of 2025. Aeroelectric and electric ejector ramjet first stages are how the U.S. will further lose space, this is almost classic Innovator’s Dilemma. The U.S. failed to lead on electrification scaling and cost reduction, the critical enabling technology for most everything else. As Marx said, they who own the means of production rule the world.

Electric Ramjets:

Ramjets can have thrust to weight ratios around five times higher than turbojets (~40:1 has perhaps been achieved and much higher is likely now possible), are efficient and can fly at speeds of up to around Mach five, have few moving parts, and can be low-cost. But they depend on speed to compress intake air and do not start generating substantial thrust until around Mach one and are generally more optimal for cruise rather than acceleration, often needing variable geometry intakes for high supersonic speed. A rocket or turbojet is often needed to get the ramjet to operating speed. For example, the Blackbird largely bypassed its gas turbine at high-speed with around 75% of its thrust effectively coming from ramjet type operation. Electric ramjets have recently become practical where an electric fan is used to get the ramjet up to speed, or used directly in the ramjet intake to compress incoming air, enabling operation from zero speed. We unsuccessfully proposed electric ramjets to NASA more than ten years ago, but since then others have moved forward with the technology. Electric ramjets, enabled by much higher power density electric motors (~59kW/kg is now possible) and battery systems, can have thrust to weight ratios perhaps exceeding 10:1, including a high power battery. ~25kW/kg 120C lithium polymer batteries can nominally be fully discharged in 30 seconds. This is compatible with vertical takeoff and landing, enabling airbreathing first stages for space launch vehicles. The battery is only briefly needed during takeoff and initial acceleration and can be regeneratively charged once at speed in preparation for landing. Cryogenic liquid methane is perhaps the preferred fuel due to its low-cost and high performance, and further raises the possibility of cryogenically cooling electric motors for even higher power densities - in excess of 100kW/kg should be possible. The electrical conductivity of copper increases by around fivefold at cryogenic temperatures and aluminum near matches it.

Electric Ejector Ramjet:

Electric ejector ramjets are similar to electric ramjets but instead use an electric compressor to feed a combustion chamber that powers ejectors in the ramjet intake that entrain air, acting as a compressor for the main ramjet. While more complicated this uses a combustion cycle to amplify the electric air compression, significantly reducing electrical power requirements. It also avoids physically obstructing the intake with fan blades, improving pure ramjet, or scramjet, operation. By locating the intake to the electric air compressor inside the ramjet before the combustor the compressor inlet pressure is increased, significantly reducing the electric compressor power required. Cryogenic liquefied methane fuel might be used to cool the electric motor, and perhaps motor controller. It might also be used to cool the incoming air to the electric compressor via a Sabre engine like heat exchanger. This could reduce electrical power requirements by up to a further ~3x. With the significantly reduced electric air compressor power requirements, as compared to a pure electric ramjet, the electric ejector ramjet can be significantly lighter. Thrust to weight ratios exceeding 20:1 are likely possible. Regenerative charging of the battery system is also possible with this configuration once the engine is at speed.

The electric ejector ramjet might also explore virtual methods for moving and controlling shockwaves, perhaps reducing the need for variable geometry inlets and improving operational robustness. For example, the electric air compressor might be used to create small air jets in critical locations that are used to create shockwaves. A small controllable air jet directed forwards out of the nose cone being an obvious example. Virtually extending the nose cone forward while also providing cooling to the nose cone. Other virtual shockwave inducing technologies include lasers, microwaves, plasma flows, and so forth. Electric ejector ramjets are closely related to air-augmented rockets and using a rocket engine with electric turbopumps to power the ejectors that entrain airflow in the intake is an even higher thrust to weight ratio option, although this necessitates an oxidizer.

Advantages:

Electric ejector ramjet first stages have numerous advantages over rocket first stages:

Fuel use and overall intrinsic cost is roughly halved.

Electric ejector ramjets can have much greater reliability and longevity, with fast turn-arounds and high utilization rates.

Gravity losses are greatly reduced so the rocket vehicle can be small and it can fly more slowly through the atmosphere, avoiding high aerodynamic loads.

Aerodynamic lift and horizontal takeoff can be efficiently used if desired. Staging can occur at substantial and safe distances from the launch site.

Ground takeoff is much quieter and safer than for a rocket launch and launch range costs can be substantially reduced.

Rocket ignition occurs at altitude, likely over unpopulated areas or out over the sea. The abort options are much better.

With small size reentry temperatures are significantly lower enabling much easier and longer lived reusable reentry shielding.

Testing is much faster and safer, and all stages can return directly to the launch site at high efficiency, enabling rapid turnaround times, very high flight rates, and low costs.

The prototyping and testing cycle time can be much faster, enabling much faster iteration and learning curves.

Economics:

With a two stage rocket vehicle it requires around 10kg of liquified methane to put 1kg of payload in orbit. The index price of natural gas is a little under $0.20/kg so the intrinsic fuel cost is around $2/kg of payload. There is also biomethane potential at these costs and scales. The cost of mature transport modes is typically around 3x to 5x the fuel or energy cost and launch vehicles would likely cost similarly once they achieve a mature industry status with many hundreds of daily launches (~$10/kg). With electric ejector ramjet first stages propellant use and total cost can be roughly halved (~$5/kg), and so electric ejector ramjet first stage launch vehicles are another technology that can be expected to disrupt two stage rocket vehicles as soon as they reach market scale. Scaling rates and associated cost reduction curves are now dominating technology adoption and markets with continual disruption being the expectation. New technologies can no longer assume a long period of market dominance over which they can generate substantial revenue. Disruption now often occurs even before market maturity is achieved. New technologies need to be optimized around iteration rates, mass production, and scaling rates, if they are to be successful and electric ejector ramjets are relatively simple engines that can be rapidly developed.

The current launch industry is predicated on large payloads and very low flight rates. There were only 251 successful launches in 2024 and the total payload launched was around 1,900 metric tons for an average payload of around 7.5 metric tons. A single electric ejector ramjet first stage might be capable of up to 10,000 launches per year and hundreds of electric ejector ramjet first stages would be needed for manufacturing scale, and they would need to be distributed around the world, for a truly mature and competitive industry. Noting that it takes roughly 90 minutes to orbit the Earth, a fully utilized reusable orbital rocket vehicle, operated in a manner similar to passenger jets, might also achieve up to around 5,000 launches per year. Cost reduction, especially with electric ejector ramjet first stages, scales mostly with flight rate, not payload size, and current markets, even assuming extreme market scaling rates, can not yet support high flight rates. This problem becomes even worse if we assume very large two stage rocket vehicles with ~100 metric ton payloads - only nineteen such launches would nominally be needed to serve the entire 2024 market. The need for large launch vehicle sizes is driven primarily by aerolosses that more greatly impact smaller rocket vehicles (largely avoided with electric ejector ramjet first stages), and a lack of orbital assembly capability. Although it may not seem like it, the space launch industry is an immature boutique industry with launch vehicles and payloads largely custom designed and manufactured. There is no shipping container approach to space logistics with the ability to assemble large satellites in space, everything must currently be shipped to space fully assembled (ISS excepted). Although companies are starting to work on this problem.

What the optimal payload size is for a launch vehicle that uses an electric ejector ramjet first stage is not entirely obvious, they do have the potential to scale to quite large sizes. Smaller payloads enable higher flight rates and lower per mass launch costs for a given market size. There are also some small scale impediments around fixed costs, minimum gauge constraints, low Reynold’s number inefficiencies, and so forth. Human beings are not easily subdivided and should probably use a buddy system for safety. Combined with associated life support and other systems this perhaps suggests a minimum payload capacity of around one metric ton. Satellites would also need to generally conform to this payload size, which is mostly possible. For context, Starlink satellites weigh around 800kg and Gen 3 Starlink satellites might weigh around two metric tons. Orbital assembly is needed for larger satellites and space missions. In some cases this might be accomplished directly and autonomously in orbit with modular design and docking maneuvers. The availability of much lower cost space launch at smaller payload sizes will favor the development of payloads to match, larger payload sizes will cost more to launch on a per mass basis. With electric ejector ramjet first stages, payloads are also less aerodynamically constrained, they can have proportionately much greater volumes. Interestingly, there are effective ways to construct very large habitat modules and orbital assembly hangars within the one metric ton payload shipping container limit that can then facilitate large scale orbital assembly systems. There are also ways to combine smaller rocket vehicles and electric ejector ramjet first stages to launch much larger payloads while maintaining relatively low launch costs.

To first approximation, a 1 metric ton payload system can achieve the same flight rate and cost reduction as a 100 metric ton payload system at 1/100th the development cost and market scale. This can also happen much more quickly. Electric ejector ramjet first stages enable this, and while there are still some disadvantages associated with such small scales, much larger launch vehicles also have their problems. At the 1 metric ton payload size an orbital rocket vehicle might have a dry weight less than 1 metric ton and weigh around 10 metric ton fully fueled with payload. If desired the orbiter might use electric ejector ramjets for landing. Electric ejector ramjet first stages enable the complete re-envisaging of rocket vehicles and much higher payload fractions - a lot of mass can be removed. The electric ejector ramjet first stage might also weigh around 10 metric tons fully fueled. Many different 1 metric ton payload launch systems using an electric ejector ramjet first stage can likely be developed and achieve high launch rates and tipping point launch costs of around $100/kg within 3-5 years, and this might cost less than $100m per effort. Especially if generic electric ejector ramjet first stages are shared between multiple launch companies. Once the potential of electric ejector ramjet first stages becomes apparent, including the consequences of being left behind in the new AI space race, billions of dollars in funding might become available. This would further accelerate the development of electric ejector ramjet first stage enabled launch vehicles - so maybe they will happen in less than five years.

Additional markets:

Electric ejector ramjet first stages enable rocket vehicles to reach anywhere on the planet in around an hour at costs comparable to passenger jets. The propellent requirements and costs are significantly less than for orbit and the index cost natural gas (methane) is around a third that of jet fuel. Electric ejector ramjet first stages enable much higher safety rates than two stage ground launched rocket vehicles and are more compatible with air/space ports near population centers. The global civil aviation market is around $1 trillion/year and accessing even a small part of this could substantially help with increasing flight rate and reducing cost. Safety would likely significantly limit the size of this market in the short term as it takes many years to develop and demonstrate high safety rates and achieve certification. It is not possible to demonstrate passenger jet level safety rates without flying millions of times.

Electric ejector ramjet aircraft might be capable of vertical takeoff and landing, cruise speeds of up to Mach ~5, and thousands of miles of range. Given that the engine cost can be quite low and design margins can be reasonable the aircraft might also be relatively low-cost. With the much higher speed they might be able to fly as many as five trips in the same time that a passenger jet flies one, greatly improving capital utilization. Much smaller and/or fewer aircraft can serve large markets. While supersonic flight is on the order of half as efficient as subsonic flight the much lower cost of liquified natural gas, as compared to jet fuel, more than makes up for the difference. In addition to being ~5x faster and able to fly more directly from smaller airports or even large helipads, electric ejector ramjet aircraft could potentially be cost competitive with existing passenger jets. Electric ejector ramjets do necessitate supersonic flight and associated sonic booms, which need to be mitigated if they are to be flown over land.

Military Applications:

The direct military applications for electric ejector ramjet first stages, aircraft, and drones are substantial and world changing. Unfortunately most of them are not defensive in nature and they are sufficiently obvious that not raising awareness of them would likely lead to imbalances and a lack of prepared defenses against them. Firstly, space dominance will likely lead to terrestrial dominance. Secondly, the ability to deliver large “packages” anywhere around the world in around an hour at very low cost would bypass a lot of military logistics and remove a lot of the security associated with distance. Everyone would effectively become close neighbors, and militarily speaking, the world would become a very small place. Thirdly, using small electric ejector ramjet hypersonic drones to deliver “packages” with thousands of miles of range at very low-cost is another obvious and more immediate threat. Fourthly, electric ejector ramjets are highly applicable to air defense systems, which is a positive. Fifthly, there are many others.