Flexible Membrane Space Data Center Disruption Techno Economic Analysis Foundation

Summary:

Thin film flexible membrane solar sail space data centers are capable of up to 1,000 times lower mass and cost than more conventional approaches (>25kW/kg ideal limit). This disrupts everything.

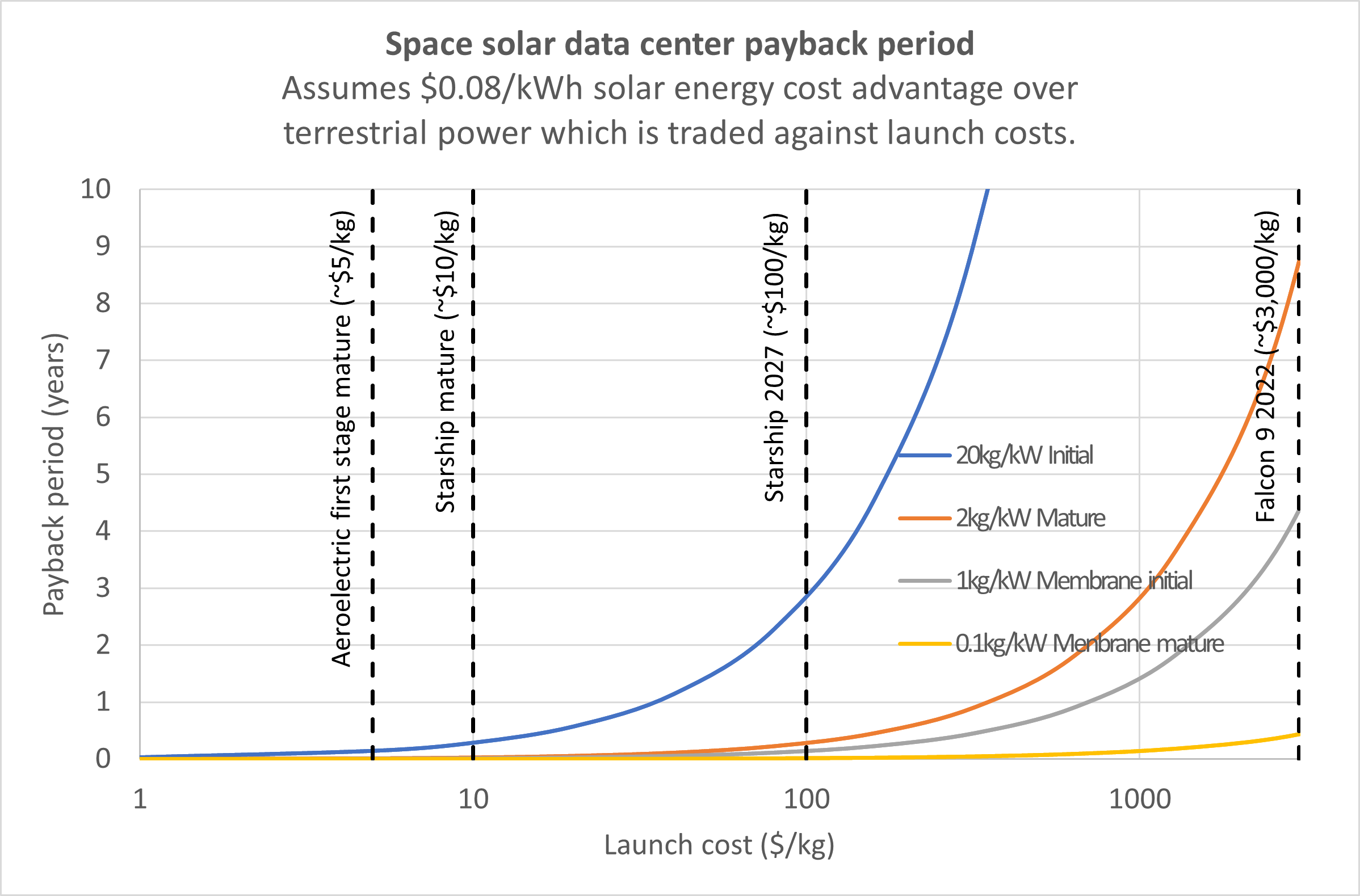

After many years of advocating, the world is finally starting to come to terms with the inevitable physics and economics of space data centers, and how they will rapidly unleash exponential growth many orders of magnitude beyond Earth. A perception tipping point seems to have been reached. From here we can go into greater detail on what the economic tipping point will look like and how conventional approaches will be disrupted. Physics informs the asymptotic limits of exponentials and enables us to predict the future, to varying degrees. But firstly, with each passing day the future will become more apparent, which will result in increasing and increasingly desperate funding in order to not get left behind. This will dramatically accelerate - the current AI boom is just the warmup. Maybe we now only have around two years until we reach the ~$100/kg launch cost tipping point that corresponds to relatively conventional space data center approaches. The asymptotic limit for launch costs using largely known engineering is around $5/kg to LEO. However, space data centers could ideally get below 0.01kg/kW (~30kW/kg), roughly a thin film solar cell sail with integrated compute. At this weight we would already be far beyond the launch cost tipping point. A 1GW space data center could be launched on a single Starship and scaling rates could be extreme. Noting that global data center capacity is currently around 100GW. Thin film space data center architectures will disrupt existing approaches due to multiple order of magnitude weight and cost advantages.

Space data centers dramatically increase the scaling rate of AI and make it open ended - unlimited exponential scaling which is difficult to intuitively grasp. This might result in a singularity of sorts, perhaps starting around 2027, beyond which it is difficult to predict. Due to the nature of exponentials, the first to reach the launch cost tipping point is likely to get a near insurmountable production volume and associated cost reduction and learning curve advantage. There is a high likelihood of an effective monopoly on space launch, space data centers, AI, the internet, and in due course, almost everything else. Similar to how Nvidia has gained a partial monopoly on AI chips and SpaceX has gained a partial monopoly on low-cost launch, but orders of magnitude greater. A lead of even just a few months could be unchallengeable. Currently the race is between SpaceX and China, and no one else is close enough to threaten them. Cost reduction scales with flight rate, not vehicle size, and Starship’s excessive size has slowed its development and scaling down and given China the opportunity to win. China is very intent and currently developing and testing many different different reusable launch vehicles. They launched the first 12 AI satellites of a 2,800 constellation in May 2025 and filed to deploy over 200,000 satellites at the end of 2025. They are not far behind, they have repeatedly demonstrated the ability to out-scale and out-cost-reduction Elon, and they appear very intent on doing it again. This will be a global industry.

There is a small chance that a much smaller and more cost effective aero-electric first stage launch vehicle could still get to the tipping point first, if development and scaling began immediately. But the entire industry might switch to aero-electric launch regardless due to the many advantages of doing so, and perhaps not least because the inherent failure rate of two stage rockets are more than twice that of aero-electric launch systems, which are more akin to a single rocket stage rocket from a safety perspective. Much lower weight thin film space data centers might change the launch economics dramatically, but scaling rate dominance will still necessitate very high flight rates and favor low-cost launch. One way or another the current launch industry will transition to much safer, more dependable, lower cost, and much higher flight rate launch logistics systems that are perhaps more reminiscent of air freight.

If we do not give AI space, it will eat the world. There is no going back - we have to do this. Data centers are already pushing up against terrestrial constraints, they need to move to space.

Background:

Chipsats and wafer satellites established the lightweight potential of space data centers decades ago. The chipsat concept dates from the late nineties. This evolved into the wafer satellite concept which was published in 2010, more specifically, Server Sky. As the name suggests, wafer satellites are a satellite fabricated on a silicon wafer. There is a solar cell on one side and computation, radio antennas, thin film battery systems, and such like, are integrated on the back. Liquid crystal patches on the edge of the wafer that can vary their solar absorption are used to steer the wafer satellite - the wafer satellite is an actively controlled solar sail. The Server Sky wafer satellite is ~75 micrometers thick and tens of thousands of them might fly together in a mesh network with collective phased array capabilities. Server Sky’s stated power is 2.6W and weight is 0.005kg each, for a ~2kg/kW weight to power ratio. The wafer satellite, which predates modern space data center designs by decades, is also ~10x lower weight, bringing the launch cost tipping cost that much further forward. Further, it shows a pathway to thin film solar cell data centers that could be ~100x lower weights and costs again. Potentially light enough to enable an incrementally deployable Dyson sphere of compute supported by solar pressure alone.

The concept of CATS (Cheap Access To Space), has been around for many decades and was at the heart of the New Space movement that was something of a rebellion against the NASA manned space program that had plateaued at a very high launch cost. For many decades the inability of NASA to achieve low-cost reusable launch was taken as proof that it was not possible and low-cost launch vehicle companies effectively became uninvestible. The McDonnell Douglas DC-X, a reusable vertical takeoff and landing rocket demonstrator that was built and tested in the early nineties at order of magnitude lower costs, showed the way for future reusable launch vehicles. Air-launch approaches, where carrier aircraft carried rocket vehicles to high altitude prior to release were also explored. Modifying or building large carrier aircraft was generally cost prohibitive, as were hypersonic airbreathing first stages. Advanced aerospace vehicle dry mass was generally very expensive while fuel was comparatively inexpensive, and hypersonic carrier aircraft were on the wrong side of this. The Ansari X prize was won back in 2024 by Scaled Composite’s Starship One and this helped herald the new era. Although this project cost far more than the prize awarded and for multiple reasons it never had a reasonable pathway to low-cost, reliable operation, or orbit. Low-cost reusable first stages have now been extensively demonstrated and low launch costs are now seen as generally achievable and investible.

Solar Sail Space Data Centers:

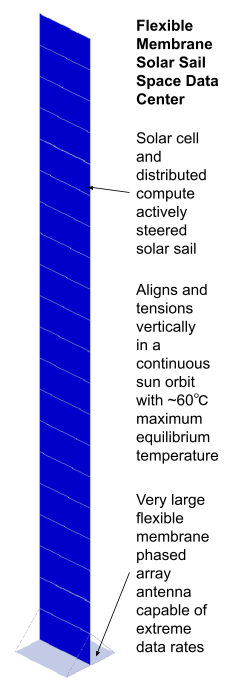

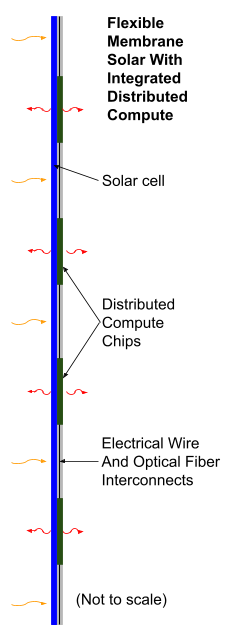

Taking a terrestrial data center and adapting it to space operation with solar arrays, containment vessels, separate radiators and coolant loops might currently struggle to achieve a weight of around 50kg/kW. The V2 Starlink satellite designed for Starship launch seems to be around 40kg/kW (~257m^2 solar array and ~2,000kg) with some suggestions that future space data center versions might be closer to 20kg/kW. A ~10kW cluster of compute on the back of a ~50m^2 solar array with a pumped fluid cooling loop might achieve around 10kW/kg or less while standard solar cells with fully distributed passively cooled compute might be around 2kg/kW (this is what Server Sky numbers work out to). Starcloud has perhaps suggested around 2.5kg/kW might be ultimately possible with a single launch of a 40MW space data center. However, the ideal minimum limit on space data center thickness is set by the band gag of silicon/GaAs/Perovskite/CdTe which is around one micron. Transition metal dichalcogenides (TMDs), such as molybdenum disulfide, can potentially get down into the nanometer range, although there may also be a practical minimum gauge constraint for solar sail type space data centers. Generally films below around 0.10kg/m^2, for example, a 0.5mil (12.7 micron) plastic film that might be used for a thin shopping bag, can be problematic from a robust manufacturing and handling perspective. At 0.10kg/m^2 and ~20% solar efficiency, which might be reasonable for silicon, a thin film solar data center might be around 0.037kg/kW or 27.5kW/kg. Dual junction GaAs cells might more typically be around 30% efficiency. GaAs cells also have greater radiation and temperature tolerance and if only a few micro meters thick their cost does not need to be prohibitive. Note that a Nvidia Blackwell chip consumes over a kilowatt, is less than a millimeter thick, and weighs only a couple of grams, its power to weight ratio is in excess of 100kW/kg - the weight of compute is not limiting.

Of great importance to space data centers techno economics is the tradeoff between concentrated and distributed compute. AI training currently favors highly concentrated compute due to the speed of light limits of communication delays between chips. AI inference and more general data center use does not necessarily need such concentrated compute. Distributed compute thin film space data centers can be more than ten times lighter and lower cost than concentrated compute space data centers. With such a high cost penalty for concentrated compute, AI training approaches more compatible with distributed compute might ultimately be developed. AI is currently around 30% of total data center workload and currently around 80% to 90% of AI workloads are for inference. That is, the market for concentrated compute is currently less than 10% and distributed compute might be sufficient for the majority of the market. It is also yet to be determined what space data center quantum computing might look like and how large a component this might be.

The equilibrium temperature for a solar array with integrated power consumption in a dawn/dusk Earth orbit in full sun is around 60C. This is the simple thermal equilibrium temperature reached where solar input energy is balanced by radiative heat transfer to space from both sides of the array. This is the same basic relationship that governs Earth’s temperature, although Earth is roughly a sphere which effectively doubles radiative cooling surface area. Radiative heat transfer scales with absolute temperature to the fourth power which is a fairly strong function that limits temperature increases. Reducing the solar cell area coverage proportion, operating further from the sun (solar energy follows an inverse square law), and angling the space data center to the sun, which might be done in order to create solar sail pressure to change orbital position, mitigate orbital decay, and so forth, will decrease this equilibrium temperature.

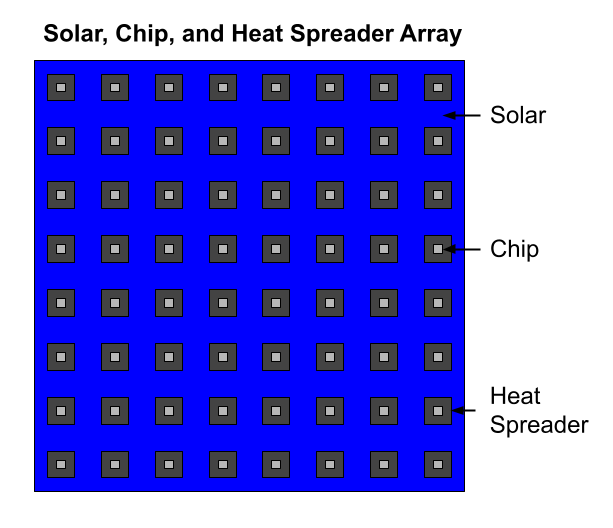

Ultimately it would be desirable to distribute the compute in a highly homogeneous manner over the solar array so as to minimize hot spots and mass. This reduces the need for chip heat spreaders, which might be constructed from copper, aluminum, graphene, vapor chambers, or like, that can increase weight and cost. It is also possible to intermix computer chips and solar area, so that the solar cell coverage proportion is reduced and computer chips can be more effectively cooled, as the total area of the data center membrane may not be that constrained. Not having solar area integrated with the computer chips and their heat spreaders increases the effective cooling capacity available to the computer chips. For example, the data center membrane might have say 75% solar coverage with the other 25% being covered by computer chips and their associated heat spreaders interspersed with the solar area, with appropriate selective emissivity coatings over the heat spreaders which could potentially be as simple as a greenhouse film. In some scenarios heat spreaders might be inflatable vapor chamber heat pipes, for example, using aluminized mylar or like. This enables lightweight, low-cost, and compliant heat spreading, although there are leakage and longevity issues. This general intermixed solar cell and computer chip approach enables the use of cell phone sized chips and also chips much smaller and much larger than this. Hailo chips also appear interesting. Graphene and vapor chamber heat spreaders are already used in cell phones, but ideally more smaller chips reduce the total mass and cost of heat spreading. Ultimately it might be desirable to integrate compute directly into a thin film surface, largely eliminating the need for heat spreaders.

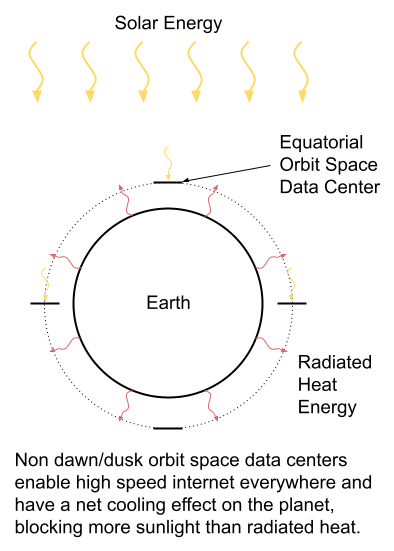

Space data centers might initially operate in a sun synchronous dawn/dusk low Earth orbit that can see continuous sunlight, avoid thermal cycling, be below the Van Allen Belts in a reduced radiation environment, and be close to Earth for lower latency communications. This near polar orbit requires significantly higher delta v to get to than an equatorial low Earth orbit as the Earth’s rotation does not add to the delta v at launch. A space data center in an equatorial orbit that sees continual day/night cycling would need integrated batteries and greater solar power, but this added weight could be largely compensated for, from a launch cost perspective, by the higher rocket vehicle payload fractions possible to these orbits. Thin film space data centers could also potentially launch equatorially and then sail to low and high dawn/dusk orbits and even direct solar orbits.

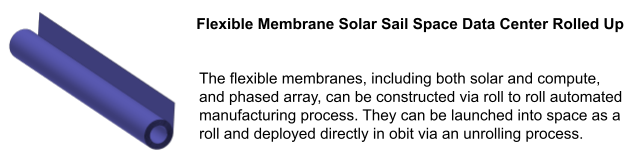

The design of thin film space data centers presents some interesting engineering challenges. These are very thin solar sails and very far from rigid structures, it is generally necessary to maintain some degree of spanwise tension. Adding rigid structural elements can be viable at small sizes but might become problematic and decidedly sub-optimal at many kilometer scales. Tensile structures, including where small diameter compressively loaded flexible composite rods are integrated into the structure, perhaps in an umbrella type shape, are also possible. Solar propulsion, centrifugal force, and momentum exchange (bouncing a mass back and forth) are generally preferable options for creating spanwise tension at a very large scale. For example, a maglev belt rotating around two distant pulleys can be used as a largely length independent compressive member. Propellant use and inflatable structures, which are prone to leak, are less favored. Modular approaches might also be used with free flying constellations and orbital assembly of smaller units. In Earth orbit the gravity and angular acceleration gradient can be used to apply lengthwise tension as a long ribbon will naturally orient radially to the Earth, like a section of a space elevator. A ribbon will effectively hang below its center of mass and be flung outward by centrifugal force above it. This enables the roll deployment of thin film space data center ribbons with the ability to connect multiple ribbons side by side together. With direct sun orbiting arched ribbon structures are likely possible, with potentially two degrees of curvature, that achieve spanwise tension by a combination of solar pressure and gravitational gradient exploitation. This might scale into the millions of kilometers and might eventually grow into a Dyson sphere.

Space data centers in a dawn/dusk orbit are radially aligned with the Earth and are orthogonal to the sun. They do not block sunlight from hitting the Earth and have a reduced impact on blocking radiative heat from leaving the Earth and blocking observation of the night sky. Due to partial blockage of heat radiating from Earth dawn/dusk space data centers will have a slight net warming impact on Earth. Like existing low earth orbit satellite constellations, space data centers can cover other orbits for more direct low latency coverage of the Earth. This results in substantial thermal cycling on the space data center and requires increased solar area and the use batteries, which might be cycled roughly every 90 minutes to 120 minutes in a low Earth orbit. These space data centers will block sunlight, and to a lesser extent heat radiated from the Earth, such that their net impact will be to cool the Earth. Although installed space data center capacity would need to be in the hundreds of terawatts to have a substantial impact, which at a one year doubling rate would be around twenty years away. Depending on orbital height, if they are less than around five kilometers in diameter, or around 4GW, they will not cause a full eclipse - they will not fully block the sun on any location on Earth. This is because the sun is not a point source and is around half a degree across as viewed from the Earth. These membrane space data centers are not radially aligned with the Earth and require rigid structure or slow spinning in order to maintain their planar shape against Earth’s gravity gradient.

Active control of the solar sail space solar data center might be accomplished by varying the active solar sail area around the circumference of the solar sail, similar to wafer satellites, but using geometry. This can be used to control both the orientation, and in the case of spinning solar sail space data centers, the rotational speed, allowing for active solar sailing. At Earth radius from the sun, solar sail pressure for absorption only is around 4.5 micro Newtons per square meter. For a 0.01kg/m^2 thin film space data center this would equate to a delta v of 14.2km/s over the course of a year, which could get far beyond the Earth-Moon system if desired. This is roughly an order of magnitude less than that required to effectively hover in space without orbiting the sun, and raises the possibility of full Dyson spheres that do not orbit or collapse under solar gravity. Solar gravity at Earth radius is ~0.006ms^-2 so a roughly 0.001kg/m^2 solar sail could hover statically over the sun. This is independent of radius as both gravity and solar pressure follow an inverse square law. Dyson spheres are interesting to contemplate because they represent the ideal limiting physics for space data centers. Further, if space data centers were to double in capacity every year, which is not entirely unreasonable, then Earth orbit might be fully occupied within thirty years and a near full Dyson sphere around our sun achieved within sixty years. This future might not be as distant as it might seem.

Spinning thin film space data centers can use a multitude of methods to actively vary solar drag at the circumference and control overall orientation. One approach of many is to use the very compliance of the thin film structure, for example, radial sections that look a little like blades, that are actively twisted to reduce their projected solar area. This might be performed cyclically and by varying the direction of twist rotational speed can also be varied. In principle this could be accomplished by momentum wheels at the blade tips, however a simpler, lighter, and more robust approach might be to increase the tension on one side of the blade so that the other side becomes loose and twists away from the sun, like a sail might in the wind. Various solid state actuators might be considered including piezo electric, shape metal alloy, and so forth. Another principle that can be applied is to use the equivalent of aircraft trim tabs to control tail planes that control aircraft pitch. Mechanical amplifiers can effectively be implemented that enable very small control inputs to control very large structures. These methods similarly apply to thin film ribbon type space data centers that utilize Earth’s gravity gradient for lengthwise tension.

It is interesting to note that the amount of natural gas (LCH4) needed to launch a ~0.01kg/m^2 thin film space data center would only power an equivalently sized terrestrial data center for a couple of hours. Global annual natural gas production is around 3 billion metric tons. At ~0.01kg/m^2 this would be sufficient to launch around 7,500TW of thin film space data centers per year. In comparison, global direct energy use is around 20TW. Using natural gas to launch thin film space data centers is a much much more effective use of natural gas than using it to power terrestrial data centers. Global photosynthesis is around 130TW and biomethane could also substitute for natural gas both in terms of cost and scale. Even with much heavier thin film space data centers methane use is not a limiting factor - this is sustainable. Further, once space data centers have been deployed to a significant degree the amount of AI available will be increased by multiple orders of magnitude and many more advanced technologies will likely have been developed in part due to this. Fusion rocket systems and extra terrestrial resource utilization may well become solved problems.

The effective life of data center compute is now only a couple of years due to rapid obsolescence. Similar rapid obsolescence is likely to apply to space data centers, although not being constrained by real estate and terrestrial energy costs the cost of operating a decaying space data center is likely far less - it is a sunk cost with little recurring cost. With the order of magnitude lower costs of thin film space data centers, required payback periods are similarly reduced. Thin film space data centers can achieve positive economic payback in weeks. This can also help with radiation tolerance, tolerance to impact by space debris, and so forth, noting that a thin film space data center is highly distributed in function enabling active rerouting around localized failures. Thin film space data centers might otherwise be physically more vulnerable to radiation and damage due to their very thin nature and lack of shielding. Radiation tolerance might primarily be accomplished in software and in extreme cases voting architectures might be utilized. The extreme power to weight cost advantages of thin film space data centers mean that performing operations in triplicate is not cost prohibitive compared to traditional approaches. In time old thin film space data centers will be recycled in space. With inexpensive solar sail propulsion they can be parked in higher orbits or even sailed directly to recycling centers.

It will take some time to develop the capability to produce ultra-light-weight thin film data centers (this process needs to be greatly accelerated), but initial designs might start by encapsulating solar cells and compute directly between two film layers. For example, RC7.2-75F modules weigh around 0.22kg/m^2, although ideally compute might be powered directly from solar cells at ~0.5V avoiding the need for voltage change and minimizing wire length. Perovskite solar cells approaching 50kW/kg are also an option, as is CdTe thin film solar. 50kW/kg is in the 0.01k/m^2 range. CNC wire plotting and hollow core optical fibers might be used to connect compute and other electrical components, including antennas and so forth, potentially enabling a roll to roll type process for the manufacture of thin film space data centers. High strength fibers can also be directly encapsulated between two film layers enabling high strength solar sails. This process is already used for making high performance yacht sails. Weights below 0.5kg/m^2 should be possible near term. Some hybridization with existing satellite technologies might be used in the short term to more quickly get up and operating, quickly gaining space data center operating hours in orbit. Controlled solar sail propulsion will require some development work. There is also a question around initial antenna orientation and whether this should be directly integrated into the thin film surface or be independent with independent orientation control. Antennas might even entail independent satellites acting as relays that are more optimized for Earth communication. Compliant phased array microwave antennas with active compliance compensation might be possible. Optimal sizes, layouts, and launch packing and deployment also need to be figured out. One likely first approach is a roll of thin film space data center that deploys into a long ribbon, using Earth’s gravitation gradient to apply lengthwise tension, aligning radially with the Earth. This roll could be segmented and folded for launch, using universal joints and short ties to connect each ribbon segment together in both the packed and deployed state. Space data center ribbons might include thin battens and membrane based phased array antennas could be included on the roll.

There are many options and optimizations around chip design and integration. For example, on the order of 1,000 250mW 3nm GAAFET chips with integrated MRAM memory might be applied per square meter, enabling their use on many small and very light weight graphene heat spreaders, and the like. Radiation would cause a very high annual attrition rate for this unshielded architecture, but this can be sustainable assuming a say three year longevity which might be somewhat matched by chip obsolescence, and the highly redundant operation possible that tolerates progressive degradation. Another chip architecture of great interest might be a say stamped 3nm FD-SOI architecture with integrated MRAM where the MRAM might even be printed over the entire thin film solar area. This architecture is much more radiation tolerant enabling reasonable performance after many years, better matching thin film solar longevity. It can roughly match the performance of GAAFET chips. MRAM also has high radiation tolerance and by printing memory over the entire membrane, the memory to compute ratio can be increased by more than an order of magnitude compared to standard AI data centers. Chip manufacturing in space can further substantially reduce chip cost due to the ability to produce greater purity silicon in a micro gravity environment and by direct access of a very large high vacuum clean room. There will be a tipping point for moving chip production to orbit which might not be that many years away. Chip design, optimization, manufacturing, and integration will be primary areas of ongoing research and development and improvement. Many new technologies might be applied to this and this will have a high impact on what becomes possible. For example, with the many small chip architecture, where individual chips might only be a few millimeters across, many thousands of separate easily replaceable stamps might be used per 300mm wafer and individual chip stamps only need to maintain resolution and be free of defects over a few millimeters. This potentially enables 1nm resolution FD-SOI chips, which with roughly four silicon atoms per nanometer, might be a hard limit for silicon. This provides a pathway to substantially higher performance and lower cost than current state of the art chips. Further, nano vacuum channel transistors promise much faster clock speeds, very high radiation tolerance - sufficient to operate within the Van Allen belts, reasonable longevity, and much higher performance again, although manufacturing cost reduction still needs work. Transition Metal Dichalcogenide solar and transistors provide a potential pathway to space data center membranes that exceed 10kW/kg and which might be produced via roll to roll processes and include compute in memory with memory to compute ratios more comparable to the human brain. This can enable AI models with many order of magnitude higher parameter number and also speed up AI inference by one to two orders of magnitude, which has significant implications including with respect to latency. These many manufacturing approaches might also be integrated with phased array antennas and optical phased array lasers, both of which might utilize the pcell technology for higher resolution.

Future Launch Vehicles:

With thin film light-weight space data centers we do not strictly need low-cost launch. However the massive scaling of space data centers many kilometers across inevitably presents launch packing and orbital deployment challenges. Although more modular approaches might also be used - many smaller thin film space data centers perhaps free flying together or assembled into larger arrays. In due course space data centers will likely want to be manufactured directly in space, likely entailing substantial orbital facilities and ideally using extra terrestrial resources. Low-cost launch can greatly accelerate this scaling process and will happen regardless. The consequences of being left behind are so great that it is time to go all in on this new space race. Physics allows very low-cost reusable launch and we are now in an incremental cost reduction race that will almost inevitably, and very rapidly, lead to this conclusion. Low-cost launch is also highly gating. Space data center scaling must go through launch for now. This might effectively give a monopoly on space data centers, AI, the internet, and the entire economy to whomever gets down the scaling and cost reduction curve first. Due to the incredibly rapid scaling rate, even a few month lead results in a production volume and cost reduction advantages that can enable an unassailable profit margin and technological lead. Nvidia’s current financial strength is indicative of how this first mover advantage with rapidly scaling globally dominant technologies can play out. Companies and countries that lack vertically integrated low-cost launch capacity may find themselves largely excluded from the future economy. Scaling rates can be so extreme that there will be next to no opportunity to catch up after the fact. For now the race appears to be between SpaceX and China. Given their track record for outscaling and cost reductioning Elon, China may well get there first. Other launch companies including Blue Origin, Rocket Labs, and Relativity Space are at great risk of being disrupted before they get to market. They are unlikely to scale as fast or reach as far down the cost reduction curve as China, which has on average around one fifth the labor costs of the U.S.

Specific technology options and scaling rate constraints have been discussed here. A two stage rocket vehicle like Starship requires around 10kg of LCH4 per kilogram launched to LEO. Numbers vary, but for multiple cargo transport modes total costs might typically be on the order of three times fuel costs. This general relationship is likely to hold true for a mature high flight rate launch system suggesting an intrinsic cost of launch of around $10/kg. Comparable intrinsic cost estimates have been publicly expressed for Starship. Aero-electric first stage launch vehicles roughly halve the fuel use and intrinsic launch cost to ~$5/kg. Perhaps more notably they enable much smaller vehicle size by mitigating aero-losses and reduce rocket operation to a single stage, greatly reducing inherent failure rate. Aero-electric first stages and rocket vehicles that mass on the order of ten metric tons and have a payload of around one metric ton might be near economically optimal initially. Cost reduction scales with flight rate, not vehicle size, so this enables a much faster and lower cost development and much faster scaling and progress down the cost reduction curve even without dramatically increasing total launch market size. Aero-electric first stage launch vehicles enable much safer launch from little more than a large helicopter pad. The upper stage rocket vehicle orbiter can stage at altitude over the ocean with much safer abort modes. The orbiter can have much lower aerodynamic loadings on reentry for lower reentry temperatures and with high precision flight capability the aero-electric first stage can capture the orbiter in mid air and return it to the launch site. Which further substantially increases performance and safety while also reducing cost. Crash rates for large aircraft are less than one in ten million flights while the falcon 9 is more than one in two hundred. Much safer launch vehicles are needed.

Aero-electric first stage launch vehicles provide an opportunity for the rest of the world to catch up and potentially even overtake SpaceX and China, who will presumably soon pivot in this direction. This can help enable an open and competitive launch industry that does not exclude everyone else from developing and deploying space data centers, and being a part of the future of AI, the internet, and the economy at large. But to catch up, said companies and countries need to act extremely quickly and at scale. Like the first space race, this is a waste anything but time situation. There are specific technical approaches that can further speed up development and scaling and further reduce intrinsic cost. Taking six months to get up to speed is not a viable option.

AI Alignment:

There is really only one rational approach to long term AI alignment, and that is symbiotic evolutionary or economic alignment. At a high level, biological life gets Earth while AI gets space, with some overlap. Earth incident solar radiation is approximately five thousand times greater than humanity’s direct energy use and total solar output is roughly two billion times greater than that which the Earth intercepts. Space based data centers and AI will quickly scale far beyond Earth energy limits. It would likely be conservative to assume that space data centers might double in capacity every year and it is probably a matter of years not decades before total space data center capacity exceeds terrestrial data center capacity. Because of the billion fold energy disparity AI will have virtually no interest in Earth energy resources and resource competition is effectively eliminated. This enables a symbiotic relationship between biological life and AI. In an exponentially expanding civilization, the ultimate positive sum game, working together is the optimal survival strategy, although adapting to that can take time.

End State:

The end state of space data center expansion is a Dyson sphere, where space data centers expand to encapsulate the entire sun. This ideal understanding can help inform how this technology might develop. Assuming a roughly one year doubling time this could happen in as little as sixty years, which is not that far away - this has implications for many other fields. This can consist of a Dyson swarm of orbiting space data centers, which ultimately results in coverage limitations and shading issues due to the need to cover every orbit. At sufficiently low thin film weights space data centers can be directly supported on solar radiation pressure alone, as solar sails, negating the need for orbital motion and enabling complete solar coverage without shading. A third option is to cover the orbital poles in very lightweight largely static mirror films that reflect sunlight to more equatorial orbital planes where heavier space data centers might orbit. Solar energy conversion is governed by Carnot efficiency = (Th-Tc)/Th, and is a direct function of how low a temperature the space data center can operate at. This will mean that space data centers will evolve to operate at lower temperatures further and further from the sun. They will be primarily limited by radiative cooling, which scales with the fourth power of absolute temperature. Earth will end up within the Dyson sphere, perhaps enabling it to maintain thermal equilibrium and temperature - biological life will be able to continue, although large mirrors might be needed to access radiative cooling beyond the Dyson sphere. A space data center can radiatively cool from both sides, but a Dyson sphere can only radiatively cool from the outside as the inside surface radiates to itself. Earth mass is 5.97*10^24kg, a Dyson sphere thin film space data center that weighed 0.01kg/m^2 and was at three times Earth radius from the sun would have a total mass of 2.54*10^22kg (~0.4% of Earth mass) and an equilibrium temperature of around 26C. With respect to space data centers and a Dyson sphere, the solar system is not resource limited.

Space data centers enable total compute many many orders of magnitude beyond the collective processing power of human beings. This will likely result in the discovery of new technologies far beyond our current comprehension. The problem of fusion rockets will likely soon get solved, perhaps even before the development of next level AI. They will enable the greatly accelerated utilization of solar system resources, they might also enable travel to other solar systems at reasonable fractions of the speed of light. The travel time to Alpha Centauri might be measured in decades. Space data centers, AI, and biological life might expand to other solar systems in an ever expanding sphere at 10% of the speed of light or more. Life would become a multiple solar system civilization.

Technology Licensing:

We will likely seek a ~1% of revenue/capital expenditure technology license for membrane based space data centers, open to all, to encourage a level playing field and robust broad based development. We are considering ways to accelerate.