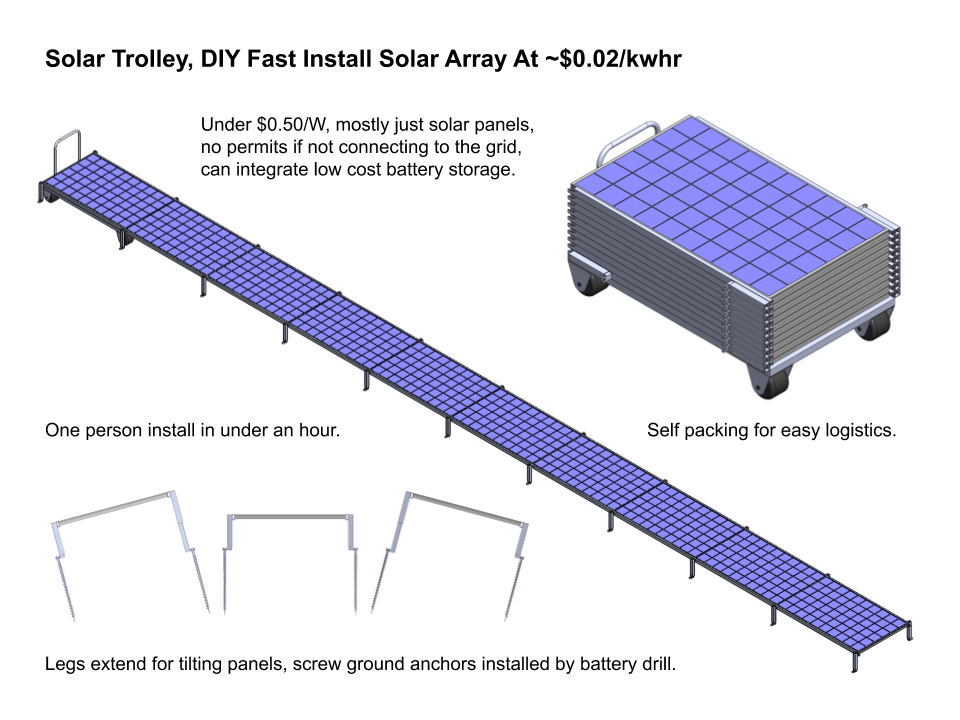

Solar Trolley For $0.02/kWh Consumer Electricity Now!

Summary:

Residential roof top solar is now under $0.03/kWh in Australia but in the U.S. it is languishing at around $0.10/kWh due to bureaucratic inefficiencies, delays, and stalled competitive industry development. This is greatly slowing scaling rates, increasing electricity prices, and slowing data center and AI deployments. A solar trolley can be deployed directly by residential customers who have adequate space, bypassing regulatory costs and enabling $0.02/kWh direct to the customer now! With the ability to be manufactured on an automotive like production line at very low-cost it can scale extremely rapidly and enable the U.S. to catch up on low-cost renewable energy. A solar trolley is basically a DIY trolley of solar panels that can be rolled out, anchored, and connected by a customer in less than an hour and used to provide electricity to charge electric cars or power a house via a backup generator transfer switch. This avoids the need for grid connection and gaining permission from an electricity utility. Battery storage and even a backup generator can be directly integrated at very low-cost, enabling full electricity utility independence at lower electricity costs than the utility can provide. The average cost of electricity across all sectors in the U.S. is around $0.14/kWh, residential only is around $0.18/kWh. Electricity grid distribution alone costs around $0.10/kWh on average. With an integrated battery system and backup generator the solar trolley could potentially provide year round electricity directly to the customer at around $0.05/kWh. This would scale extremely rapidly and disrupt the U.S. electricity supply, greatly reducing electricity costs for consumers and relieving the existing grid such that it could better serve AI data center growing demands.

Background:

Solar modules are now commercially available for under $0.10/W (<$0.005/kWh), but rooftop solar in the U.S. averages around $2.50/W installed. Last year China installed 277GW of solar while the U.S. only installed 50GW. Unsubsidized residential rooftop solar in Australia costs around $0.03/kWh while it costs around $0.10/kWh on average in the U.S., so this is not just a consequence of higher labor costs. High solar costs in the U.S. are primarily due to poor regulation and corresponding lack of installation speed, efficiency, and a scaled competitive industry. This is not something that the U.S. can rectify in a few years, even if it had the will to do so, and it is putting the US economy and the scaling of AI in the U.S. at a huge competitive disadvantage. In the long term the optimal solution will be to fully clad buildings and roofs directly in solar, as this enables ~$0.02/kWh co-located electricity, does not require additional land, and scales to serve almost all of our energy needs. In the short term we desperately need a technology solution that bypasses undeveloped industries, regulatory hurdles, and electricity utilities. The solar trolley approach enables this, it is similar to the previously described solar trailer concept but sized for smaller applications and residential use, including temporary rental properties.

Solar Trolley:

The solar trolley carries a stack of solar panels that can be quickly deployed in a DIY manner with integrated structural support, legs, ground screw anchoring, wiring, and so forth. The solar trolley can be rapidly assembled on an automotive like production line at a very small multiple of solar panel cost. A single production line might quickly produce 100,000 solar trolleys a year (~1GW/year). This enables rapid scaling of the technology. The solar trolley might directly plug into a backup generator transfer switch (around $1,000 to $2,000 to install), at the main electrical panel of a house or building via a long outdoor rated power cord. It might also be used directly to recharge an electric car. In this way it bypasses the electricity grid and associated permissions, regulations, and costs. A backup generator and transfer switch is often now a sunk cost in locations vulnerable to grid outages. Battery storage and a backup generator can be directly integrated into the solar trolley to enable year round grid independent operation. Electric car batteries might cost as little as $100/kWh, with LiFePO4 batteries costing even less, while household battery storage might cost around $1,000/kWh installed. For example, the Tesla Powerwall. Integrating battery storage directly into the solar trolley on the automotive production line enables a nearly 10x reduction in battery storage cost. This is achieved by bypassing installation and independent grid connection costs. A small inexpensive backup generator can be integrated and used to bridge times when solar power might be insufficient. The solar trolley is so low in cost that excess capacity might be installed such that a backup generator is rarely needed. The solar trolley is limited by land availability, which is why full solar cladding is preferred in the long term, however, it is a temporary structure that can be DIY installed in less than an hour without regulatory permissions and it can be quickly moved as needed.

Economics:

The solar trolley is scaled around standard solar modules and little additional structural mass and cost is required. It might also fit in the back of a pickup truck or van for easy DIY transport. A 10kW solar trolley might consist of say twenty large 500W solar modules. At $0.10/W the raw cost of 10kW of solar modules would be around $1,000. Additional costs would include the trolley for carrying them, short legs, ground screw anchors, and electrical cables for connecting the solar modules together and connecting the solar trolley to the electrical load. The added raw cost of the additional components might only be an extra $1,000 or so. For safety and shading reasons the solar trolley might operate at under 50VDC with all of the modules connected in parallel, this necessitates heavy cables but this is not cost prohibitive. Shading or failure with one solar module would not stop the solar trolley from operating. A 10kW solar inverter might have a raw cost in the $1,000 to $2,000 range. If we assume a ten year equivalent life with say 30,000 equivalent full power sunshine hours this equates to around $0.01/kWh. But there will be additional supply chain distribution costs, and so forth, hence the $0.02/kWh base estimate. There will also be ongoing cost reductions and given that solar tends to come down in price by around 20% for every doubling in production volume solar costs might further halve over the coming years.

Adding battery storage to the solar trolley will substantially increase cost. Because the solar trolley is not grid connected and can be assembled on an automotive production line it can take advantage of electric car battery cost structures. Electric car battery costs are approaching $100/kWh while grid scale battery costs in China are closer to $50/kWh. This is getting into the $0.02/kWh per charge cycle range. In contrast, the Tesla Powerwall costs around $1,000/kWh. So a solar trolley with integrated battery storage might still be under $0.04/kWh with an upfront capital cost in the $5,000 to $10,000 range. A small backup generator costing a few hundred dollars could be added to this so as to get through winter. Fuel costs are comparatively high and this is expensive to run, however this might only be on the order of 10% of total electricity production and it enables the grid connection to be cut. On average a grid connection might effectively cost around $1,000 a year, although in many cases, like for remote customers, it can be much more. In the long term thermal photovoltaic generators powered by combusting municipal waste and/or biomass or low-cost biofuels might be used at much lower cost.

Another interesting economic trend that is happening is that rooftop solar in Australia at ~$0.03/kWh and ~40% adoption is competing directly against grid scale solar and grid utilities that are providing electricity at an average of ~$0.26/kWh USD. Australia is now curtailing solar extensively and this will only increase because of this cost differential. Rooftop solar will continue to scale and be sized around electricity needs at the start and end of the day and in winter when solar production is lower, resulting in yet greater midday curtailment. A consequence of the high cost of grid electricity distribution is that grid scale solar will be curtailed before rooftop solar, co-located battery systems will also provide much lower cost electricity than grid scale and grid dependent battery systems. This means that grid scale solar will quickly have very low utilization rates and become uninvestable. Likewise grid scale battery systems will become uninvestable. The U.S. is substantially behind Australia with rooftop solar and co-located battery systems but grid scale solar and battery systems will eventually become uninvestable here too. Distributed solar and battery systems, such as the solar trolley, will take over from grid scale solar and battery systems.

Impact:

The solar trolley is a leap-frog low-cost renewable energy technology solution that would enable the U.S. to catch up with China. It would dramatically lower the cost of energy for many U.S. consumers to around $0.05/kWh, avoid the need for substantial grid upgrades, and it could effectively power rapid data center scaling via substitution. Its primary limitation is that it is land constrained; it is only viable for residential, commercial, and industrial sites that have access to the prerequisite land required to deploy it. A 10kW solar trolley requires around 50sqm or 500sqft of land. The U.S. population is around 27% urban, 52% suburban, and 21% rural. Solar trolleys are likely applicable to many suburban sites so the potential market should still be large enough to have a big impact on national energy use. Solar trolleys can be deployed and scaled rapidly and they will further establish renewable energy precedent and accelerate more integrated solar solutions such as rooftop solar and solar cladding.