Expandable Solar Trailer For ~$0.02/kWh Electricity And Rapid Scaling

Summary:

The U.S. has fallen far behind the rest of the world on low-cost solar energy and is losing AI because of it. Solar trailers can be scaled extremely rapidly on an automotive production line at very low cost. They enable around $0.02/kWh solar energy for anyone with the land available to deploy them. A 20 foot long solar trailer might extend to a length of 200 feet and hold around 25kW of solar modules. It might be deployed in a matter of hours with ground screws used to anchor each leg. Low-cost battery storage can be pre-integrated. Arrays of solar trailers can be quickly connected together to create massive solar farms in the many megawatt and even gigawatt scale. This technology can be manufactured and deployed fast enough to meet the dramatically increasing energy needs of electrification and AI. A single automotive production line might produce over 10GW of solar trailers per year. Solar trailers are also mobile structures, avoiding many regulatory costs and delays, and able to be moved as needed. They can be installed rapidly and co-located with large energy users, avoiding the need for slow and costly grid connections.

Problem:

Solar modules are now commercially available for under $0.10/W, but rooftop solar in the U.S. averages around $2.50/W installed. Last year China installed 277GW of solar while the U.S. only installed 50GW. Unsubsidized residential rooftop solar in Australia costs around $0.03/kWh while it costs around $0.10/kWh on average in the U.S., so this is not just a consequence of higher labor costs. High solar costs in the U.S. are primarily due to poor regulation and corresponding lack of installation speed, efficiency, and a scaled competitive industry. At the grid scale, energy costs in the U.S. are over twice what they are in China, leading to a direct competitive disadvantage in AI, the future of which is dictated by energy availability and cost. While numbers vary, it seems likely that China already has lower cost compute than the U.S., and this seems to be more critical than having the latest chips. They also have over half the world’s AI engineers.

Concept:

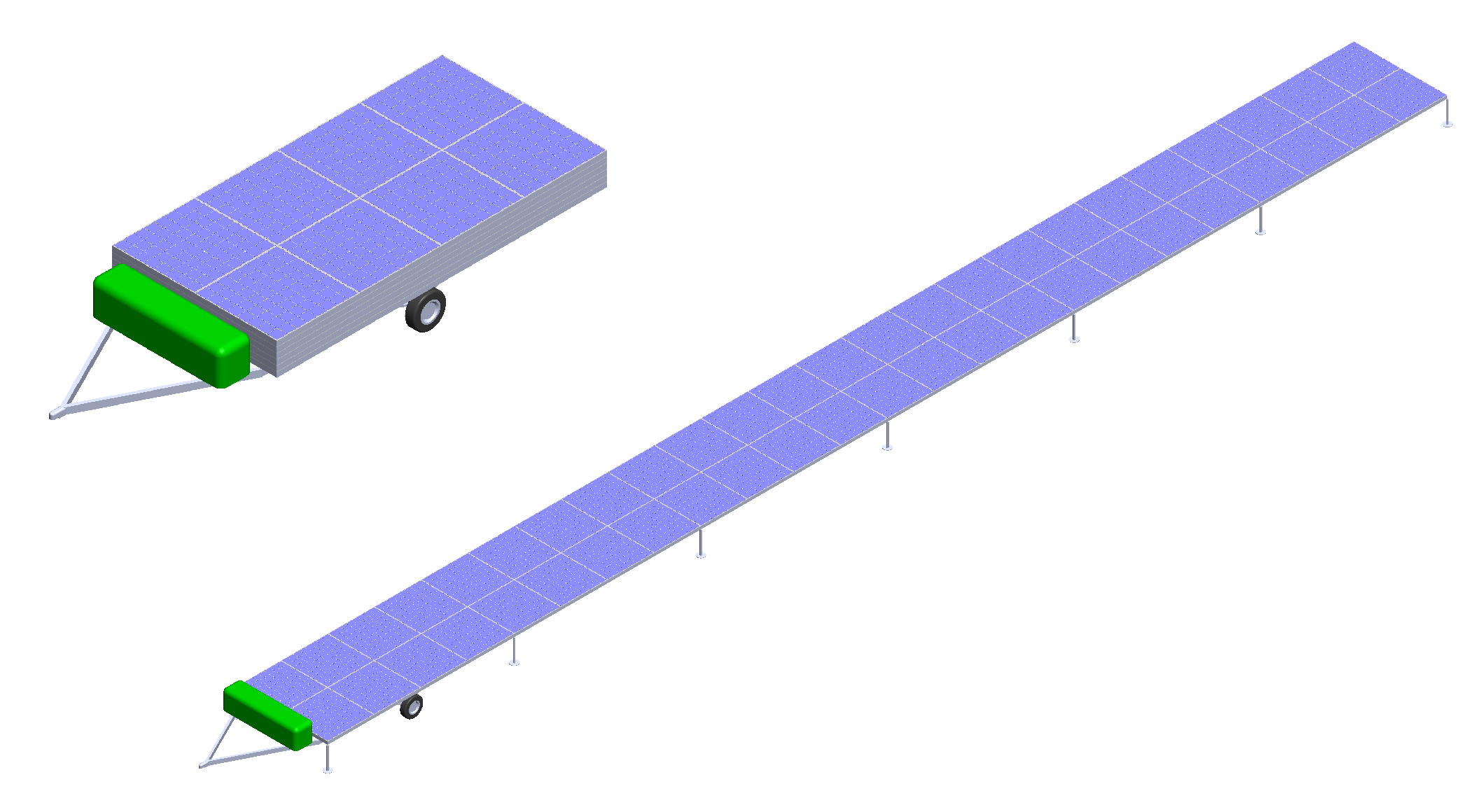

Solar trailers enable low-cost mass production of large solar systems on automotive production lines that can scale very rapidly. They also enable most of the electrical work to be performed in a factory and bypass substantial regulatory costs by being temporary structures. Like a motorhome that can be quickly anchored with small ground screws and they can have different length legs that allow for fixed tilting, not that tilting is particularly necessary given their low-cost. Solar modules are now extremely low-cost, as low as $20/m^2, and their cost might be expected to halve again as production volumes continue to increase. As a general rule, solar module cost has decreased by around 20% with every doubling in production volume. The solar trailer primarily consists of solar modules. These are supported by a minimal steel frame along with legs, wheels, and a tow bar. Frames for each layer of solar are made to slide along the frame beneath and off the back of the trailer with a pair of legs at the end of each frame so that the trailer can be towed slowly, laying down solar frames as it goes. The process is reversed for packing the solar frames back onto the trailer for transport. Electrical wiring is pre-integrated into the solar frames in the factory, likely with connectors in between frames to minimize wiring length and allow for easy replacement and reconfiguring of solar frames. The solar trailer might cost a few times as much as the solar modules that it incorporates, likely under $0.50/W, depending on location. Solar modules cost around three times as much in the U.S. as in China, which is problematic.

A battery box might be added at the front of the trailer and this allows for the integration of low-cost automotive battery packs. It is critical to note that electric car batteries might cost as little as $100/kWh, with LiFePO4 batteries costing even less, while household battery storage might cost around $1,000/kWh installed. For example, the Tesla Powerwall. Integrating battery storage directly into the solar trailer on the automotive production line enables a nearly 10x reduction in battery storage cost. This is achieved by bypassing installation and independent grid connection costs. The solar trailer effectively becomes an independent generator able to supply twenty four hour power, with reduced capacity during winter, that can be connected directly to electricity loads, including households, via a power transfer switch. The solar trailer might also be used directly for electric vehicle charging. Primary use cases for solar trailers are likely large commercial and industrial loads, including data centers. Farms are another likely use case, especially those with high power electric irrigation pumps. Many of these use cases can potentially supply electricity back into the grid via existing grid connections, greatly reducing the need for grid upgrades.

A solar trailer can operate at the relatively high voltages of grid scale solar array strings, which might be in the 1,000VDC to 1,500VDC range. Although they can also be designed for lower voltages, at the expense of heavier and more expensive wiring, which can also reduce shading losses in locations that might be sensitive to shading. Many solar trailers can be lined up next to one another with a central main power distribution line connecting them all together. This enables the fast construction of large solar farms. In some scenarios the connecting high power line might be integrated into another solar trailer, enabling fast installation of the high power connecting transmission line without ground disturbance or electricians. Voltage regulating inverters can also be integrated for more efficiently connecting disparate voltages.

Economics:

At $0.10/W solar module cost and 25kW solar trailer might include $2,500 worth of solar modules. Including frames, legs, wires, trailer, and assembly, which might largely be automated, the total cost of the solar trailer would likely be less than $10,000. Assuming 2,000 nominal sunshine hours per year, which is not uncommon in a good solar climate, and a twenty year effective life, the raw cost of electricity produced, ignoring discount rate, would be $0.01/kWh. Integrating 75kWh of battery storage, which might provide enough storage for twenty four hour operation for most of the year, might cost another $10,000. Adding a little cost margin, the solar trailer might produce daytime electricity only for around $0.02/kWh and twenty four hour a day electricity via battery storage for around $0.04/kWh. Adding a low-cost backup generator system, perhaps using a thermophotovoltaic waste to energy system, would enable year round operation, including in the depths of winter and at higher latitudes. The average price for electricity in the U.S. in August 2025 was $0.1762/kWh for residential, $0.1404/kWh for commercial, $0.0906/kWh for industrial, $0.1486/kWh for transportation, and $0.1426/kWh total. In contrast, advanced nuclear energy might cost around $0.08/kWh. This excludes grid distribution costs which are generally around $0.08/kWh again - colocation of nuclear power might not always be practical. In order to meet the growing needs of electrification and AI we need to massively scale energy production within probably the next three years. Given how far behind the U.S. now is, co-located solar trailers, in addition to being perhaps the lowest cost option, are almost the only technology that can be practically scaled, via the massive manufacturing capacity of the automotive industry, in time.

Impact:

The U.S. has fallen far behind with the commercialization and scaling of low-cost energy, specifically solar and batteries. Life is constrained by three primary things, energy, resources, and space, of which energy is likely the most critical - with enough low-cost energy resources tend to become inexpensive. For example, aluminum production is strongly dictated by the cost of electricity. For the U.S., losing energy is existential. Solar trailers present a possible pathway by which the U.S. can catch up. Deploying its struggling automotive manufacturing base to solve the low-cost energy problem and massively scale solar and battery power. Setting up a new automotive production line might take 1 to 3 years, but switching over an existing production line can happen much faster and a solar trailer is a relatively simple product. Scaling up the production of solar modules and batteries may take longer, and importing these components might be needed in the short term. While switching production lines can be rapid, scaling entire industries takes longer. Tesla scaled at around 50% per year for many years, and this might be the scaling rate that is practically possible for entire industries, but with the automotive industry we are not starting from zero. The U.S. automotive industry produces around 10 million cars annually and could produce many more solar trailers. 10 million 25kW solar trailers would have a total installed capacity of 250GW. The U.S. can quickly catch up and produce the solar energy and battery storage that it needs to power electrification and AI.

The widespread availability of co-located twenty four hour a day electricity at around $0.04/kWh would completely disrupt our entire energy system. Even at higher latitudes and in poor solar climates like Seattle the cost of energy would be dramatically reduced, especially if combined with backup generators to get through the worst of winter. This would largely end energy poverty, drive electrification and the conversion to electric vehicles, and enable us to scale AI massively. It will also have profound impacts on the cost of resources, cost of logistics, and cost production, substantially increasing prosperity, and there will be environmental benefits. This is an opportunity for the U.S. to catch up and not lose AI. Although it is also opportunity for the U.S. to drop the ball and pass the technology lead to someone else.